- sales@ron-vik.com

- 800 Colorado Ave S, Minneapolis, MN 55416

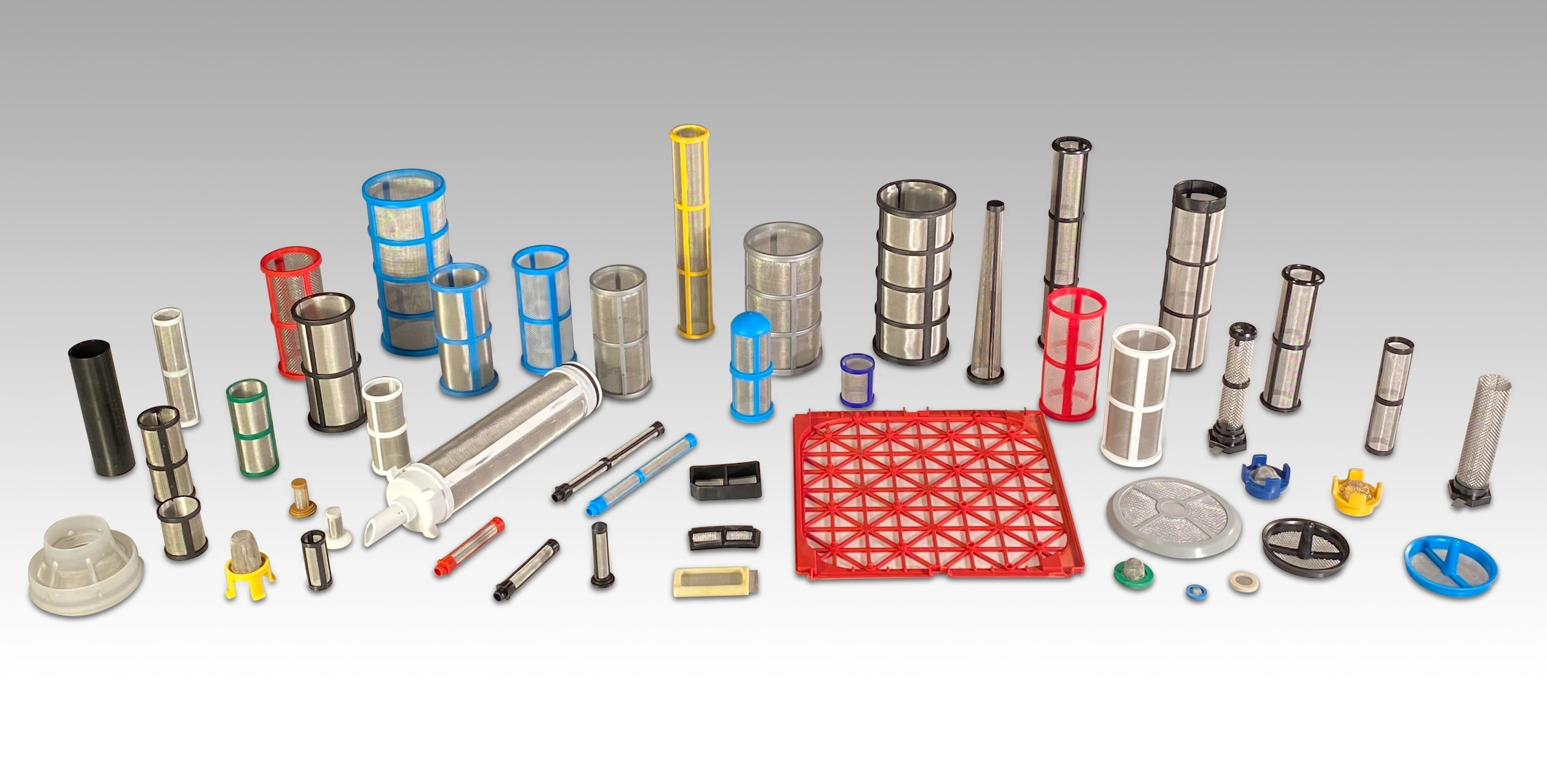

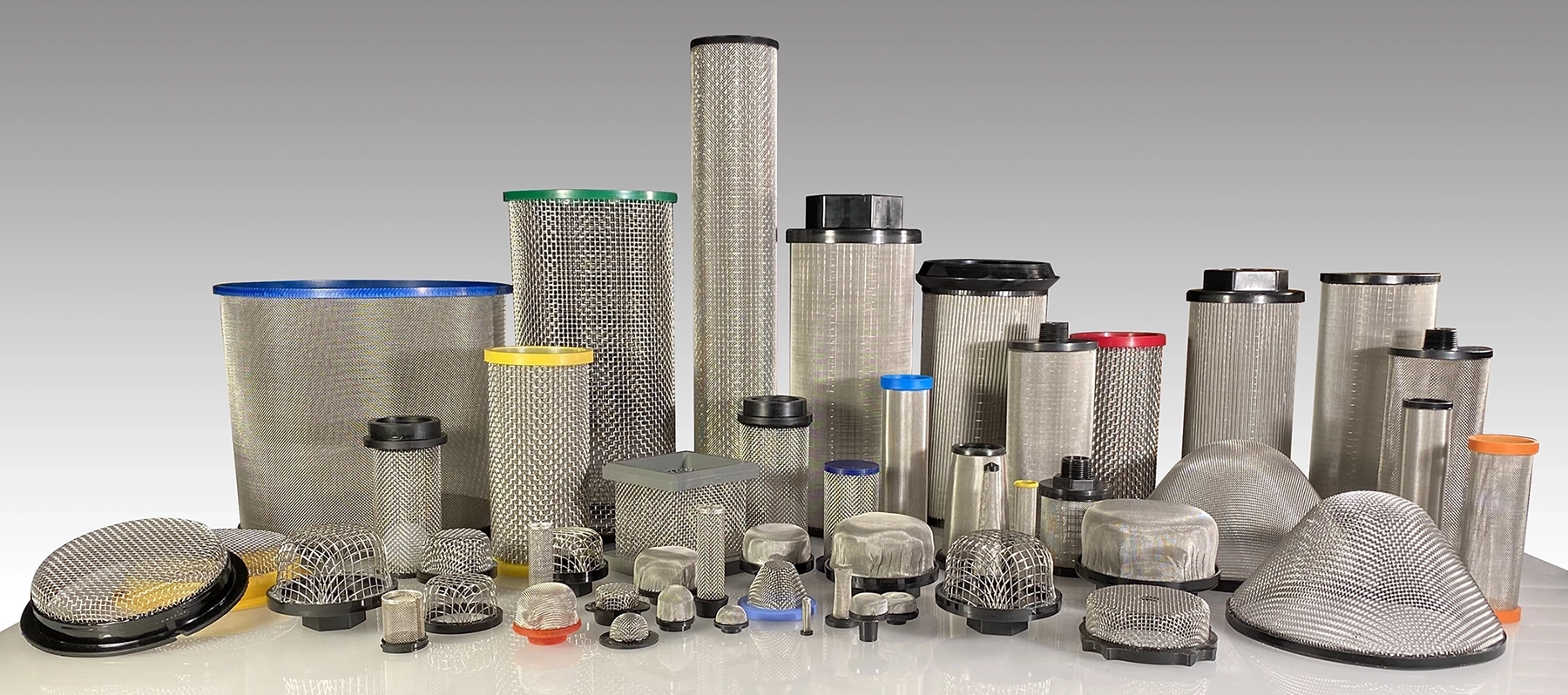

Ron-Vik has years of experience in manufacturing insert injection molded filters for our proprietary in-line strainers. We have expanded our insert injection molding capabilities to allow us to design and manufacture a wide range of insert molded custom products. Most of these products combine cylinders or mesh blanks with thermoplastics or thermoplastic elastomers (TPE's). These products offer significant advantages over metal on mesh, welded or soldered designs. These components are made by taking a prefabricated mesh form and putting it into an injection mold. The mold closes around the mesh and plastic is injected to create a gasket and/or a support cage. Our experienced engineering staff will assist you in the design of a component that will achieve your desired results.

For over 70 years Ron-Vik has been the leader in PVC pot molded filters and strainers. Our pot molding capability combines the efficient filtration of wire mesh with economical PVC flanges and/or gaskets to provide a wide array of filtration and straining products. We can mold cylinders and formed blanks with either rigid or flexible gaskets/flanges. PVC is available in a wide variety of colors and durometer ranges from 40 Shore A to 60 Shore D.